The process of making armor accessory

Materials

Copper plate (0.6 mm thick) and steel plate (0.4 mm thick) are prepared. The copper plate (0.6 mm thick) and the iron plate (0.4 mm thick) are cut out of the base plate with a pair of scissors or thread saw .

Cutting out the crown plate

The materials for the crown plate (the upper part of the armor accessories to which the metal metal ornaments are attached) is made.

It is cut out of the copper base plate using a thread saw.

Crown plate forging

Forging the materials for the crown board cut from the base plate. The shape is made with a hammer and a hollow in the wooden workbench.

Make a hole for the braid

Odoshi holes(for braid) are made in the material cut out from the baseplate. This is done using a tool called "Ekisen(Excen)". The holes are carefully drilled one by one with the aid of a rudder.

Making of Kozane materials

The beauty of the finished product is enhanced by cutting the processed materials and fine-tuning its shape according to the dimensions.

Gold leaf coating

The beautifully crafted material is coated with lacquer and finished with a gold leaf coating.

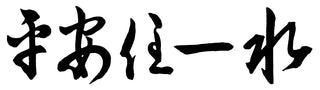

Nurihaku (Lacquered and Goldleaf-coated)

"Nuri" means lacquering, "Haku" means goldleaf coating. Gold leaf stamping (left image)& black 'URUSHI' lacquering(right image)

Odoshi (Binding)

In this process called "Odoshi", each part is connected with flat braid. The process is carried out in order to make the length of the threads and the shape of the binding sections uniform .

Armor accessory "Nikitama"

Stored in a special paulownia box.