Kyoto armor, like actual armor, is composed of many parts. Therefore, there are many processes involved, and many traditional techniques are used in the processing of the materials. In order to harmonize all of them and express a unique style, it is necessary to have a high level of skill to process all the processes consistently.

Every detail of Heianjyu Issui's Kazari armor is carefully examined by a master's eye and handcrafted with great care, allowing for the expression of unparalleled traditional beauty. Here are just a few of the many processes involved in making Kazari armor.

Connecting Hachi-ita (Helmet materials)

Hachi-ita, formed with a hammer, are joined together one by one with iron nails. In order to create a unique shape, Hachi-ita are assembled with different sizes and hammered out pieces.

Menpo (face guard) forging

The material is cut from a flat steel plate and formed into various shapes with a hammer. The photo shows a cheek being hammered out.

Kozanekiji fabric

Precision-cut boards are formed into corrugated shapes and lined. The photo shows the production of Shikoro (equipment to protect the back of the head). Fine adjustments are made to match the shape of the finished product, using intuition and techniques cultivated over many years.

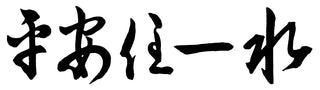

Metal ornament fabric production

Various metal fittings are processed to decorate the armor. In the photo, Kuwagata is hand-hewn and ground into a pair, then polished with charcoal to give it a unique luster.

Fukurin Wrapping

The gold-plated Fukurin is wrapped around the shin guard while tightening with a mallet.

This increases the strength of the equipment and at the same time enhances its decorative value.

Plant moustache on menpo (face guard)

The Menpo fabric is given an iron rust color and fine horsehair is planted as a moustache.

Lacquered and stamped with gold leaf

After the shape of the armor material has been adjusted, it is coated and hardened, and then the gold leaf is applied.

In the case of Urushi-lacquer, the lacquer is applied over and over again to achieve a deep luster.

Cutting of leather place

Painting leather with traditional patterns on deerskin carefully selected by a master craftsman's eye is cut to fit the shape of each part.

Odoshi processing

Bind each part of the armor with braided cords.

This is a very important process that determines the shape and beauty of the armor, and it is where the skill of a skilled craftsman is utilized.

Attaching the metal fittings

The gold-plated ornamental metal fittings are attached to each part. Since the metal fittings are processed into each shape at the fabric stage, it is necessary to attach them in place.

Cutting the gold brocade

Nishijin brocade is used for the kote (arm protectors), the haidate (thigh protectors), and the sunete (shin guards) and gives them a dignified atmosphere with a touch of glamour. and gives them a dignified atmosphere.

Installation of leather materials

The cut leather components are attached to the armor. The image shows the attachment of the leather parts to the belly.

Assembling

Carefully processed individual parts are gathered here and assembled to approach completion.

Finishing

Every detail of the completed armor is carefully finished to ensure that all parts are in harmony.

Each process of armor material, lacquering, gilding, and odoshi, as well as finishing ......, is carefully processed by hand to create a massive and magnificent work of art. Each part of the handmade Kazari Armor is a wonderful craftwork. The beauty of each piece is maximized when all of them are processed in harmony with each other.